Pump Packing Basics: Installation & Maintenance Tips.

Sep 11, 2025

Just as a finely tuned engine requires precision, pump packing is essential for maintaining peak pump performance and sealing efficiency.

For engineers and technicians, mastering the art of pump packing opens the door to enhanced operational reliability, reduced maintenance costs, and increased longevity.

1. Understanding Pump Packing

Pump packing and mechanical seals, crucial components in many pump systems, significantly influence overall efficiency and longevity.

The main function of pump packing is to create a seal around the pump shaft, where it exits the casing, thereby preventing leakage and maintaining pressure, often utilizing materials like graphite and carbon for enhanced sealing efficiency. For centrifugal pumps, in particular, optimal packing is vital for balancing the need to control leaks while allowing necessary cooling and lubrication. By tailoring the packing material and design to specific service conditions, engineers can achieve superior performance and reliability.

Moreover, understanding the types of packing—compression, automatic, and floating—enables proper selection for varied applications. Automatic packings like V rings and O rings adjust to operating pressures, while floating packings are ideal for reciprocating movements due to their slit or segmental ring designs. Compression packings, the most common, require careful installation and maintenance to perform effectively.

Ultimately, the success of pump packing relies on precision and knowledge. Selecting appropriate materials that endure operational pressures and temperatures, while adapting to environmental conditions, can drastically reduce wear and leakage. Regular inspection and adjustments ensure consistent performance, establishing pump packing as a foundational element for optimal pump functionality.

![]()

2. Types of Packing Rings

The variety of packing rings includes compression, automatic, and floating designs, each tailored for specific operational needs. These packing rings can be made from materials like metals, fibers, and high-performance synthetic compounds.

Automatic rings, such as V rings and O rings, adjust to operating pressures, while floating rings suit reciprocating movements with their segmented designs. Compression rings, widely used in rotating equipment, need precise installation and regular maintenance.

2.1. Automatic Packings

Automatic packings encompass V rings, U cups, and O rings, each designed to self-adjust under specific operational pressures.

Automatic packings enhance reliability by eliminating the need for manual gland adjustments.

They are confined to a defined space and rely on the operating pressure to activate and maintain effective sealing. This ensures minimal maintenance while maximizing efficiency and longevity.

Engineered for resilience and precision, automatic packings adapt seamlessly to different pressure variations, making them ideal for sustained, reliable performance in complex pump systems.

2.2. Floating Packings

Floating packings offer a versatile solution for sealing in reciprocating applications, utilizing specifically designed segmental rings.

- Materials: Commonly constructed from piston rings or segmental rings, sometimes incorporating springs.

- Applications: Ideal for systems requiring higher adaptability and movement.

- Design: Typically, they consist of segments that facilitate better sealing and alignment.

Their construction allows them to adjust to varying conditions without constant maintenance.

Utilized in demanding environments, floating packings provide flexibility and robust performance in sealing solutions.

2.3. Compression Packings

Compression packings are the most prevalent type used in rotating equipment due to their effectiveness and versatility.

- Static Seal: Achieved at the ends of the packing ring and the inside diameter of the stuffing box.

- Dynamic Seal: Formed between the packing and the shaft or shaft sleeve.

- Lubrication: These packings contain lubricants to prevent overheating and reduce shaft wear.

- Construction: Typically made from twisted, braided, woven, or wrapped elements, often in square cross-sections.

- Adjustment: Requires careful adjustments to avoid over-tightening and depletion of lubricants.

These packings rely on precise compression to form a seal, thus controlling leakage.

Proper installation is crucial to ensure optimal performance and longevity of the packing.

3. Adjusting Packing for Optimal Performance

Properly adjusting packing is critical to maximizing the efficiency and longevity of the sealing system.

In the adjustment process, the load on the packing must be carefully calibrated to control leakage effectively. Over-tightening should be avoided.

Adjustments should be incremental, ensuring each turn of the gland bolt is followed by a performance check. This prevents undue stress and wear on the packing and shaft.

Equally crucial is monitoring the temperature and ensuring adequate lubrication. Insufficient lubrication can lead to overheating and premature failure.

Regular inspection and maintenance are key to keeping the packing in optimal condition.

4. Selecting Materials for Pump Packing

Choosing the right materials, especially those with optimal carbon content, is paramount.

The selection process hinges upon the specific operational demands, often necessitating the use of materials like graphite for their unique properties. Each scenario requires consideration of fluid characteristics, temperature, and pressure conditions to guide material choice. For example, materials must exhibit durability, flexibility, and chemical resistance to maintain their sealing effectiveness over prolonged use.

Material compatibility with the process fluid is crucial.

When selecting packing materials, fibers such as mineral, animal, vegetable, and synthetic options offer varied advantages, based on their intrinsic properties. Metals, including lead, copper, brass, and stainless steel, add structural integrity, while common lubricants like mineral oils, vegetable oils, and synthetics reduce friction.

The rapid advancements in material science provide new possibilities, enhancing reliability and performance. By integrating innovative materials into their packing systems, industries can address evolving challenges and meet stringent operational requirements effectively.

|

Category |

Material |

Applications |

Industries |

|---|---|---|---|

|

Fibers |

|||

|

Mineral Fibers |

Graphite |

High-temperature applications, abrasive environments |

Power Generation, Mining |

|

Animal Fibers |

Wool, Hair, Leather |

Low to medium temperature applications, general-purpose sealing |

Food Processing, Pharmaceuticals |

|

Vegetable Fibers |

Flax, Ramie, Jute, Cotton, Paper |

Low to medium temperature applications, water services |

Water Treatment, Agriculture |

|

Synthetic Fibers |

Nylon, Rayon, PTFE (Polytetrafluoroethylene), Carbon, Aramid (e.g., Kevlar), Polyamide |

Chemical resistance, high-temperature applications |

Chemical Processing, Oil -AND- Gas |

|

Metals |

|||

|

Lead |

Lead |

High-pressure applications, corrosive environments |

Chemical Processing, Marine |

|

Copper |

Copper |

High-temperature applications, thermal conductivity |

Power Generation, Metallurgy |

|

Brass |

Brass |

General-purpose sealing, moderate temperature and pressure applications |

Manufacturing, Automotive |

|

Phosphor Bronze |

Phosphor Bronze |

High-temperature and high-pressure applications |

Chemical Processing, Oil -AND- Gas |

|

Aluminum |

Aluminum |

High-temperature applications |

Aerospace, Manufacturing |

|

Iron |

Iron |

High-pressure applications |

Heavy Industry, Manufacturing |

|

Stainless Steel |

Stainless Steel |

High-temperature and high-pressure applications, chemical resistance |

Chemical Processing, Oil -AND- Gas |

|

Nickel |

Nickel |

High-temperature applications, corrosion resistance |

Chemical Processing, Marine |

|

Monel |

Monel |

High-temperature and high-pressure applications, chemical resistance |

Chemical Processing, Oil -AND- Gas |

|

Inconel |

Inconel |

High-temperature applications, corrosion resistance |

Aerospace, Chemical Processing |

|

Zinc |

Zinc |

General-purpose sealing, moderate temperature and pressure applications |

Manufacturing, Automotive |

|

Lubricants and Binders |

|||

|

Dry Lubricants |

Graphite, Molybdenum Disulfide, Mica, Talc, Teflon, Carbon |

High-temperature applications, reducing friction |

Various Industries |

|

Mineral Lubricants |

Lube Oil, Paraffin, Petrolatum, Waxes, Greases |

General-purpose lubrication, moderate temperature applications |

Manufacturing, Automotive |

|

Vegetable Lubricants |

Castor Oil, Palm Oil, Cottonseed Oil, Linseed Oil, Carnauba Wax |

Environmentally friendly applications, food-grade applications |

Food Processing, Pharmaceuticals |

|

Animal Lubricants |

Tallow, Glycerol, Beeswax, Lard Oil, Fish Oil |

Low to medium temperature applications, general-purpose sealing |

Food Processing, Pharmaceuticals |

|

Synthetic Lubricants |

Synthetic Oils, Synthetic Waxes, Fluorolubes, Silicones |

High-temperature and high-pressure applications, chemical resistance |

Chemical Processing, Aerospace |

|

Examples of Common Packing Materials |

|||

|

Graphited Acrylic Packing |

Made from graphited acrylic fibers, often interlaced for flexibility and durability |

General-purpose sealing, moderate temperature and pressure applications |

Manufacturing, Automotive |

|

Flexible Graphite |

Originally cut from laminated sheet stock but now made from ribbon tape for better compression and sealing |

High-temperature applications, chemical resistance |

Chemical Processing, Oil -AND- Gas |

|

Metallic Packing |

Made from babbitt, aluminum, and copper in wire or foil form, often with flexible cores like twisted glass fiber and impregnated with lubricants |

High-temperature and high-pressure applications, thermal conductivity |

Power Generation, Metallurgy |

By selecting the appropriate packing material, taking into account the chemical resistance, temperature, pressure, and shaft speed, the longevity and efficiency of the packing in pump applications can be maximized.

5. Importance of Lantern Rings and Throat Bushings

Lantern rings, also known as seal cages, play a significant role in distributing lubricant flow to the packing. This precise lubrication minimizes friction and wear, thus extending the operational life of the packing and ensuring reliable sealing under various conditions.

Throat bushings, on the other hand, provide close clearance with the shaft to prevent packing extrusion. By maintaining this precise clearance, throat bushings help control leakage and enhance the overall efficiency of the stuffing box. In combination, lantern rings and throat bushings create a robust sealing environment, critical for optimal pump performance and reduced maintenance costs.

5.1. Function of Lantern Rings

Lantern rings, or seal cages, ensure optimal lubrication.

Their primary function is to evenly distribute lubricant to the packing. This distribution is vital for maintaining the packing's integrity and extending its operational lifespan. By ensuring consistent lubrication, lantern rings reduce the friction between the packing and the pump shaft, thereby minimizing wear. Consequently, this well-lubricated interface enables pumps to operate efficiently and reliably with minimal downtime.

Lantern rings also aid in cooling.

This cooling is particularly crucial in high-temperature applications. By facilitating the ingress of coolant fluids, lantern rings help dissipate the heat generated during pump operation.

In modern centrifugal pumps, lantern rings are positioned strategically within the stuffing box. This positioning maximizes their effectiveness, allowing for precise control over lubrication and cooling. Industries must ensure the correct placement and maintenance of these rings to harness their full potential.

5.2. Role of Throat Bushings

Throat bushings are essential components in pump packing.

These components are installed at the lower end of the stuffing box. Throat bushings are designed to create a close-fitting seal with the pump shaft, thus preventing the extrusion of packing material. Additionally, by optimizing the clearance between the bushing and the shaft, they help maintain effective sealing and reduce potential leakage points.

Throat bushings enhance the longevity of pump packing.

Their role in reducing packing extrusion cannot be understated - it is this precise function that minimizes the wear on the packing material, extending its service life. Moreover, throat bushings serve as the initial barrier against abrasive particles, safeguarding the integrity of the packing and the pump shaft.

Industries that deal with high-pressure and high-temperature applications often rely on the robustness of throat bushings and mechanical seals to ensure system reliability. Maintaining optimal clearance and regularly inspecting these components can significantly improve pump performance and reduce maintenance needs. Properly designed and installed throat bushings are integral to achieving efficient and reliable pump operation.

6. Utilizing Stuffing Box Gland Plates

Stuffing box gland plates are essential in maintaining axial load on the packing, ensuring effective sealing. These plates must be carefully adjusted to prevent overtightening while allowing sufficient compression to control leakage and lubricate the packing.

In applications where process fluid leakage poses hazards, utilizing smothering gland plates becomes crucial. Such systems introduce a neutral liquid to replace the dangerous fluid, thus mitigating risks. Proper adjustment and maintenance of gland plates can significantly enhance pump efficiency and reliability, safeguarding both equipment and operators from potential contamination.

6.1. Different Gland Plate Designs

Gland plates come in various designs, tailored to specific operational needs and pump configurations.

First, the conventional gland plate is a straightforward design that fits over the stuffing box and compresses the packing mechanically. It is adjusted manually, allowing for versatile applications where frequent adjustments may be necessary. While this design is simple, it offers reliable performance with proper maintenance and periodic checks.

Additionally, packing follower glands feature a more advanced design. In environments where the packed fluid is particularly hazardous, these glands facilitate the integration of a neutral fluid to displace the dangerous medium. This design is particularly useful in sensitive applications requiring stringent control of leakage and contamination prevention.

Finally, spring-loaded gland plates are innovative designs that automatically adjust to variations in pressure and temperature, ensuring a consistent seal without manual intervention. These plates enhance operational reliability and reduce maintenance efforts, proving beneficial in applications with fluctuating operating conditions and high demands on sealing integrity.

7. Managing Leakage and Power Consumption

An essential aspect of optimizing pump packing is managing both leakage and power consumption. Effective leakage control not only preserves operational efficiency but also safeguards against potential hazards.

The PV factor is crucial for evaluating packing performance.

This element, which calculates the pressure and velocity product, highlights the critical balance needed to minimize wear and heat generation. By understanding this factor, technicians can better predict and manage sealing effectiveness.

A disciplined approach to managing leakage involves regular monitoring and timely adjustments to the packing system. By adhering to recommended practices, operators can significantly reduce unwanted leaks, thus minimizing power consumption and extending the life of the equipment.

8. Controlling Pressure and Temperature

High pressures at the stuffing box require advanced techniques for pressure control, such as using throttle bushings, mechanical seals, or specialized valves. Proper pressure management prevents packing damage and extends pump life, reducing downtime.

Temperature control is equally critical, necessitating cooling methods based on service conditions. Efficient cooling strategies prevent overheating, ensuring the longevity and reliability of the sealing system.

8.1. Pressure Management Techniques

Effective pressure management in centrifugal pumps is crucial for maintaining optimal seal performance.

By regulating pressure within the stuffing box, operators can prevent excessive wear on packing materials and shaft sleeves. This is particularly important in high-pressure applications.

Throttle bushings play a vital role in reducing the pressure before it reaches the packing. This ensures that the packing operates within its design parameters, reducing the risk of failure.

Specialized valves and gaskets are another technique used to manage pressure effectively. These valves can modulate pressure, ensuring it remains at safe levels to protect the packing and overall system integrity.

Proper pressure management extends the operational life of the pump, reducing maintenance costs and increasing efficiency.

8.2. Temperature Control Methods

In centrifugal pump systems, effective temperature control methods are essential for optimal performance.

High temperatures can lead to the premature failure of packing materials. Therefore, cooling strategies must be employed.

For light-duty services, basic cooling methods are often sufficient. However, more demanding applications require advanced cooling techniques.

Lantern ring cooling and water-cooled stuffing boxes, often incorporating graphite and carbon materials, are commonly used solutions. These methods significantly improve heat dissipation.

Ensuring proper cooling maintains the integrity of the packing, thereby enhancing seal longevity.

9. Handling Abrasives and Environmental Factors

Liquids with suspended solids can quickly degrade packing, causing shaft wear and premature failure.

To counteract this, clean liquid injection into a lantern ring or using an external source is highly effective. Abrasive particles embed in the packing material, leading to increased friction and wear. Implementing these preventive measures helps to maintain packing integrity and extends operational lifespan.

Environmental factors also play a significant role in packing performance. By understanding these conditions, operators can select materials and designs best suited to their specific challenges and operational environments.

For facilities facing harsh environmental conditions, regular inspection and maintenance of packing systems are paramount. This vigilant approach ensures that packing remains effective and resilient, thereby boosting the overall reliability of the pump. Properly addressing both abrasives and environmental factors is integral to achieving optimal pump packing performance.

10. Installing Continuous Coil Packing

Carefully loosen and remove the gland, followed by the old packing rings using a packing puller. Assess the shaft sleeve for any damage, replacing it if nicks or scoring are present.

To install, wrap the packing around a mandrel, cut into rings, and stagger the ends by 90°. Reassemble the packing with the lantern ring, securing each ring with the gland, adjusting for optimal compression.

10.1. Step-by-Step Installation Guide

Proper installation of continuous coil packing in centrifugal pumps is essential for achieving optimal sealing performance and prolonging equipment life. Follow this methodical guide to ensure a seamless process.

- Begin by loosening and removing the gland. Extract old packing rings systematically.

- Assess the shaft sleeve for damages; ensure it is free from scoring or nicks before proceeding with new packing installation.

- Cut the packing into appropriate ring sizes, ensuring each ring fits precisely around the shaft. Stagger the ends of the rings at 90° intervals to prevent leakage paths.

- Introduce each ring into the stuffing box systematically, securing with the lantern ring if present. Adjust the gland to compress each ring fully, but avoid overtightening to maintain lubricant efficacy and prevent shaft overheating or damage.

11. Troubleshooting Short Packing Life

Short packing life can be frustrating and costly.

To diagnose these issues, one must first examine the installation procedures. Any deviation from the recommended steps in packing installation can lead to premature wear. Missing lantern rings, improper ring staggering, or incorrect packing sizes are notable culprits. Reviewing the steps meticulously can prevent these errors.

Next, consider the lubrication used.

Insufficient or incorrect lubrication leads to increased friction, causing the packing to degrade rapidly. Utilizing manufacturer-recommended lubricants and ensuring adequate distribution can extend packing life.

Environmental factors also play a crucial role in packing longevity. Abrasive particles, incompatible liquids, and high temperatures can wear down packing materials swiftly. Implementing filtration systems or cooling mechanisms can mitigate these effects and bolster packing durability.

Careful monitoring, stringent adherence to best practices, and addressing environmental challenges are vital for optimizing pump packing performance. Regular checks and maintenance will ensure reliability and extend operational life significantly.

12. Importance of Training for Proper Installation and Maintenance of Packing

Training in the proper installation and maintenance of pump packing is crucial for ensuring the longevity and efficiency of centrifugal pumps. Incorrect installation or maintenance can lead to increased leakage, excessive wear, and even pump failure. Proper training equips technicians with the knowledge to select the right materials, understand the operational conditions, and apply the correct techniques for installation and adjustments.

The Pump Systems Academy offers comprehensive training programs that cover all aspects of pump packing. These programs provide hands-on experience and detailed theoretical knowledge, ensuring that participants are well-versed in the latest industry standards and best practices. By investing in training through the Pump Systems Academy, organizations can significantly reduce downtime, lower maintenance costs, and enhance the overall performance of their pumping systems.

Proper training also emphasizes the importance of regular inspections and timely adjustments, which are critical for maintaining optimal sealing performance. Technicians learn to identify early signs of wear and potential issues, allowing for proactive maintenance that prevents costly repairs and extends the life of the equipment.

In summary, training in the proper installation and maintenance of pump packing is essential for achieving reliable and efficient pump operation. The Pump Systems Academy provides the necessary education and skills to ensure that technicians can perform these tasks with confidence and precision, ultimately contributing to the success and sustainability of their organizations.

People Also Ask

How much should a pump packing leak?

A well-maintained centrifugal pump with properly installed packing should experience a controlled and minimal amount of leakage, ensuring effective sealing while preventing overheating. A slight trickle of liquid around the packing is essential for lubrication and cooling.

Minimal leakage is expected from well-installed pump packing. It serves a vital function.

To ensure optimal performance, observation of the leakage rate is necessary. Excessive or insufficient leakage can indicate issues.

In conclusion, controlled leakage is a critical aspect of pump packing maintenance. Regular inspections and adjustments are necessary to maintain the balance between effective sealing and the cooling needs of the pump. Failing to maintain this balance can result in decreased efficiency and increased wear.

What is the purpose of gland packing in a pump?

Gland packing in a pump plays a fundamental role in sealing mechanisms, ensuring minimal leakage and maintaining the pump's operational integrity. This commonly involves controlling fluid or air escape at critical junctures within the pump.

It serves to prevent the ingress of air into the system.

Thus, gland packing ensures both internal and external pressure equilibrium.

By doing so, it sustains the pump's efficiency and protects against possible contamination.

Appropriate gland packing installation and maintenance are crucial for optimal performance and system longevity.

Consequently, effective gland packing significantly reduces the risk of mechanical failure and costly downtimes. Understanding its purpose and proper handling is key to achieving reliable pump operation and extended service life.

Should pump packing be replaced?

Recognizing when to replace pump packing is essential for maintaining optimal performance and extending the life of the equipment.

Over time, packing material experiences wear and tear caused by friction, chemical exposure, and thermal cycling, which can lead to increased leakage and reduced sealing efficiency. Monitoring the condition of the packing regularly ensures that it operates within its designed parameters and prevents unexpected failures.

Consistent leakage, even after adjustments, is a clear indicator that the packing material has deteriorated and should be replaced. Additionally, changes in the operating environment, such as a transition to a new pumped liquid or varying pressures, may necessitate the reassessment and replacement of the existing packing material.

In conclusion, proactively replacing pump packing can significantly enhance the reliability and efficiency of pumping systems. By ensuring that worn or unsuitable packing is promptly replaced, maintenance teams can minimize downtime, improve safety, and ultimately extend the lifespan of the equipment. Proactive maintenance inversely correlates with the frequency of expensive, unplanned repairs, highlighting its critical importance.

Are there other options than mechanical seals, that perform better than packing, to reduce water leakage and maintenance?

Yes.

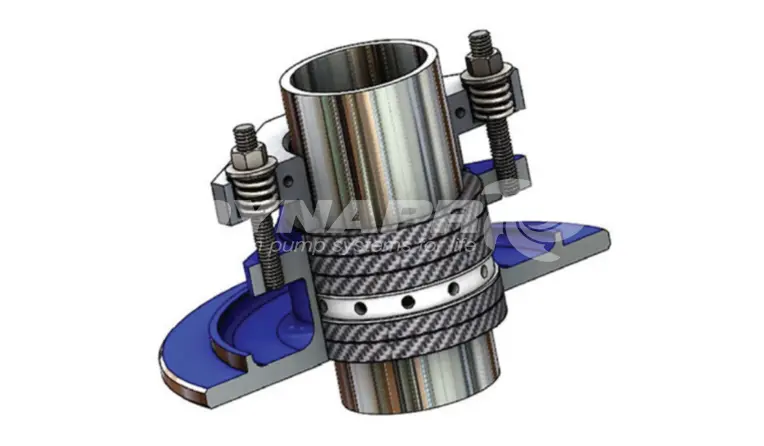

One innovative alternative to traditional mechanical seals and packing is the Dynaseal. The Dynaseal is designed to provide superior sealing performance while minimizing water leakage and reducing maintenance requirements. This advanced sealing solution combines the benefits of mechanical seals and packing, offering a reliable and efficient option for various pump applications.

The Dynaseal features a unique design that allows for easy installation and adjustment, ensuring optimal sealing with minimal effort. Its robust construction and high-quality materials make it suitable for a wide range of operating conditions, including high pressures and temperatures. The Dynaseal is particularly effective in applications where traditional packing or mechanical seals may struggle, providing a long-lasting and dependable solution.

Key benefits of the Dynaseal include:

- Reduced Water Leakage: The Dynaseal's advanced design significantly minimizes water leakage, helping to conserve water and reduce operational costs.

- Lower Maintenance Requirements: With its durable construction and reliable performance, the Dynaseal requires less frequent maintenance compared to traditional sealing methods, leading to reduced downtime and maintenance costs.

- Easy Installation and Adjustment: The Dynaseal is designed for straightforward installation and adjustment, making it an ideal choice for both new installations and retrofits.

- Versatility: Suitable for a wide range of applications, the Dynaseal can be used in various industries, including chemical processing, water treatment, and power generation.

By choosing the Dynaseal, organizations can achieve enhanced sealing performance, reduced water leakage, and lower maintenance costs, ultimately improving the efficiency and reliability of their pump systems.