Pump Efficiency Explained: Ultimate Guide

Aug 07, 2025

Centrifugal pumps are fundamental in various industrial applications, yet often their efficiency is not maximized, causing higher operational costs and energy consumption.

This poses a challenge.

Optimizing pump efficiency is crucial to enhancing performance and achieving cost savings over time. There are many factors involved to maintain and improve efficiency. It's always recommended that you work with the manufacturer of the pump and/or their IOM to evaluate any challenges you're facing with efficiency. You can also contact The Pump Systems Academy or Dynapro Pumps if your pump is within our line of interchangeable pumps.

1. Understanding Pump Efficiency

In the realm of centrifugal pumps, efficiency is a measure of how well these machines convert the energy supplied into useful work. When evaluating pump efficiency, engineers scrutinize various parameters, ensuring that every aspect of the machine—from hydraulic to volumetric components—works harmoniously to minimize energy loss, thereby achieving optimal performance and cost-effectiveness.

1.1 Definition and Examples

Efficiency in pumps is the conversion rate of supplied energy into hydraulic energy.

The typical automobile engine operates at around 20 percent efficiency, highlighting the need for innovation.

Pump efficiency measures how well a pump converts mechanical energy from its shaft into hydraulic energy such as flow and pressure, often impacted by design, operational factors, and the total head.

A common industrial example is the centrifugal pump, converting mechanical energy into hydraulic energy with efficiencies ranging from 50 to 93 percent, influenced by specific speed and component design.

1.2 Key Efficiency Metrics

Understanding key efficiency metrics is crucial for optimizing pump performance.

- Mechanical Efficiency: Evaluates energy losses in bearings, seals, and the pump's mechanical components.

- Volumetric Efficiency: Assesses the extent of leakage losses within the pump, such as through wear rings and vane clearances.

- Hydraulic Efficiency: Determines losses due to liquid friction and flow turbulence within the pump's volute and impeller.

These metrics collectively define the overall efficiency of a pump, revealing areas for potential improvement.

Engineers must analyze these metrics continuously to enhance energy conversion and operational efficacy.

2. Design Criteria Influencing Efficiency

Pump efficiency is greatly influenced by various design criteria. The primary architectural elements include the impeller and volute designs, which define how well the pump converts power into flow and pressure.

To optimize, designers must evaluate specific speed and impeller vane shapes, which significantly affect hydraulic efficiency. Additionally, the efficiency of bearings and seals are integral factors that minimize energy losses due to friction and mechanical wear.

These considerations ensure a balanced approach, enhancing both performance and durability of the pump system.

2.1 Mechanical Efficiency Factors

Mechanical efficiency in pumps is influenced by several critical components that affect energy conversion.

- Bearings: Responsible for reducing friction in rotational parts.

- Seals: Prevent leaks and minimize frictional losses.

- Stuffing Boxes: Manage leakage while maintaining mechanical integrity.

- Flexible Couplings: Ensure smooth power transmission with minimal loss.

- Gearboxes: Optimize rotational speed with high efficiency.

Bearings reduce mechanical friction, enhancing overall pump efficiency.

Proper pump maintenance, including seals and lubrication in bearings, is vital for long-term efficiency.

2.2 Volumetric Efficiency Factors

Volumetric efficiency in centrifugal pumps is crucial for minimizing losses due to fluid leakage.

- Wear Rings: Reduce internal leakage between the impeller and pump casing.

- Balancing Holes: Equalize pressure to minimize axial thrust and leakage.

- Vane Clearances: Optimize the space within semi-open impellers for reduced leakage.

Wear rings are essential components in maintaining high volumetric efficiency.

Balancing holes help manage internal pressure, reducing the potential for leakage and enhancing reliability.

2.3 Hydraulic Efficiency Factors

Hydraulic efficiency dramatically impacts overall pump performance.

This efficiency primarily hinges on minimizing losses due to liquid friction and turbulence within the pump. An optimally designed impeller and volute play pivotal roles, as their interactions dictate the smoothness of fluid flow. Specifically, vane shape and the impeller eye's diameter are critical for reducing hydraulic losses.

Vane shape directly influences efficiency.

Hydraulic efficiency can be improved by designing impellers with smoother contours. Additionally, proper clearance between the impeller tips and the volute tongue reduces undesired recirculation, further enhancing performance.

Advanced computational fluid dynamics (CFD) tools aid in refining these designs, ensuring that modern pumps achieve the highest possible hydraulic efficiency. By minimizing inefficiencies at every stage, one can extend pump life and reduce energy consumption, marking significant operational cost savings.

2.4 Combined Efficiency Factors

When analyzing pump efficiency, understanding the combined efficiency factors is crucial. They encompass mechanical, volumetric, and hydraulic efficiencies, each contributing to the overall performance.

Mechanical efficiency focuses on minimizing losses from friction within the pump's components.

Volumetric efficiency addresses leakage and flow irregularities that can detract from optimal performance.

By optimizing each of these areas, engineers can significantly enhance overall pump efficiency and reliability.

Real-world applications demand careful consideration of these factors to ensure the pump operates at peak performance across varying conditions. Managers should prioritize combined efficiency enhancements.

Ultimately, the synergy of these factors determines the pump's sustained effectiveness. Enhanced combined efficiency leads to lower operational costs and reduced environmental impact, benefiting both industry and the planet.

3. Specific Speed and Its Impact

Specific speed is a crucial parameter that characterizes pump performance by relating flow, head, and speed. It serves as a determining factor for the shape of a pump’s performance curve.

Understanding specific speed helps engineers optimize pump design, ensuring efficiency and reliability across varied applications. Selecting the right specific speed enhances overall system performance.

3.1 Defining Specific Speed

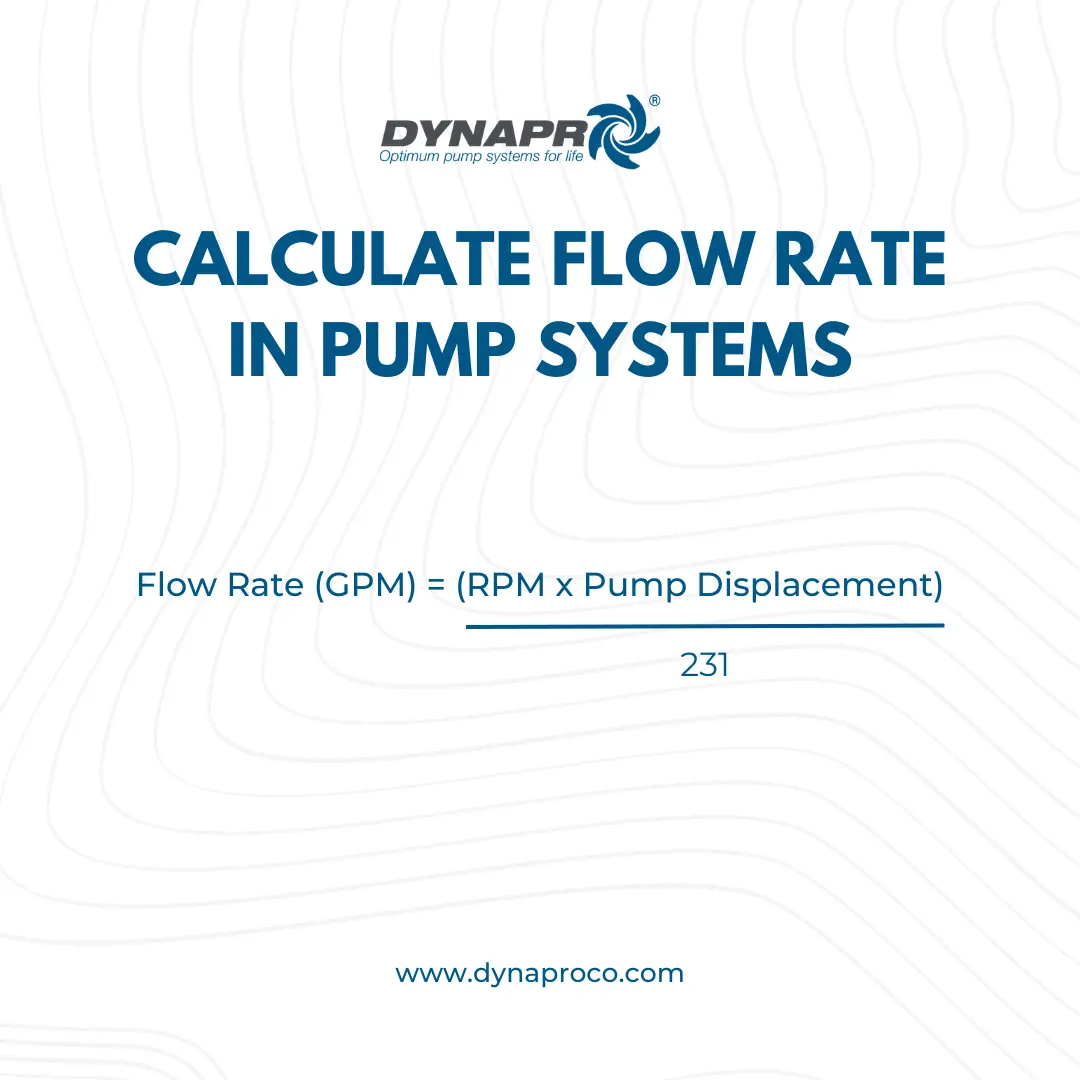

Specific speed (Ns) is a key dimensionless parameter that defines the hydraulic characteristics of a pump.

- Flow rate (Q) - typically measured in gallons per minute (GPM).

- Head (H) - the energy imparted to the fluid, measured in feet or meters.

- Speed (N) - the rotational speed of the pump, usually given in revolutions per minute (RPM).

Calculating specific speed involves these three parameters to determine pump efficiency.

High specific speed values typically indicate high flow and low head, whereas low values indicate low flow and high head.

3.2 Effect on Performance Curve

The shape of a pump's performance curve is substantially influenced by its specific speed (Ns).

- Flat Curves: Typically observed at low specific speeds (Ns ≤ 500). They provide stable head regardless of changing flow rates.

- Steeper Curves: Found at high specific speeds (Ns ≥ 3,000), offering a significant increase in head with increasing flow.

- Moderate Curves: Characteristic of mid-range specific speeds (Ns between 1,000 and 2,500), balancing the attributes of flat and steep curves.

Understanding these variations aids in selecting the appropriate pump for different industrial applications.

Designing with the right specific speed can maximize pump reliability and efficiency across operational ranges.

3.3 Importance for Efficiency

The efficiency of a pump significantly impacts operational costs and system performance.

- Energy Savings: Higher efficiency reduces power consumption and operational expenses.

- Reliability: Efficient pumps often have longer lifespans and fewer maintenance requirements.

- Environmental Impact: Lower energy usage translates to reduced greenhouse gas emissions.

- Operational Performance: Systems with efficient pumps run more smoothly and effectively.

Implementing efficient pumps ensures cost savings and improved sustainability for industrial applications.

An optimized design enhances overall system reliability and longevity.

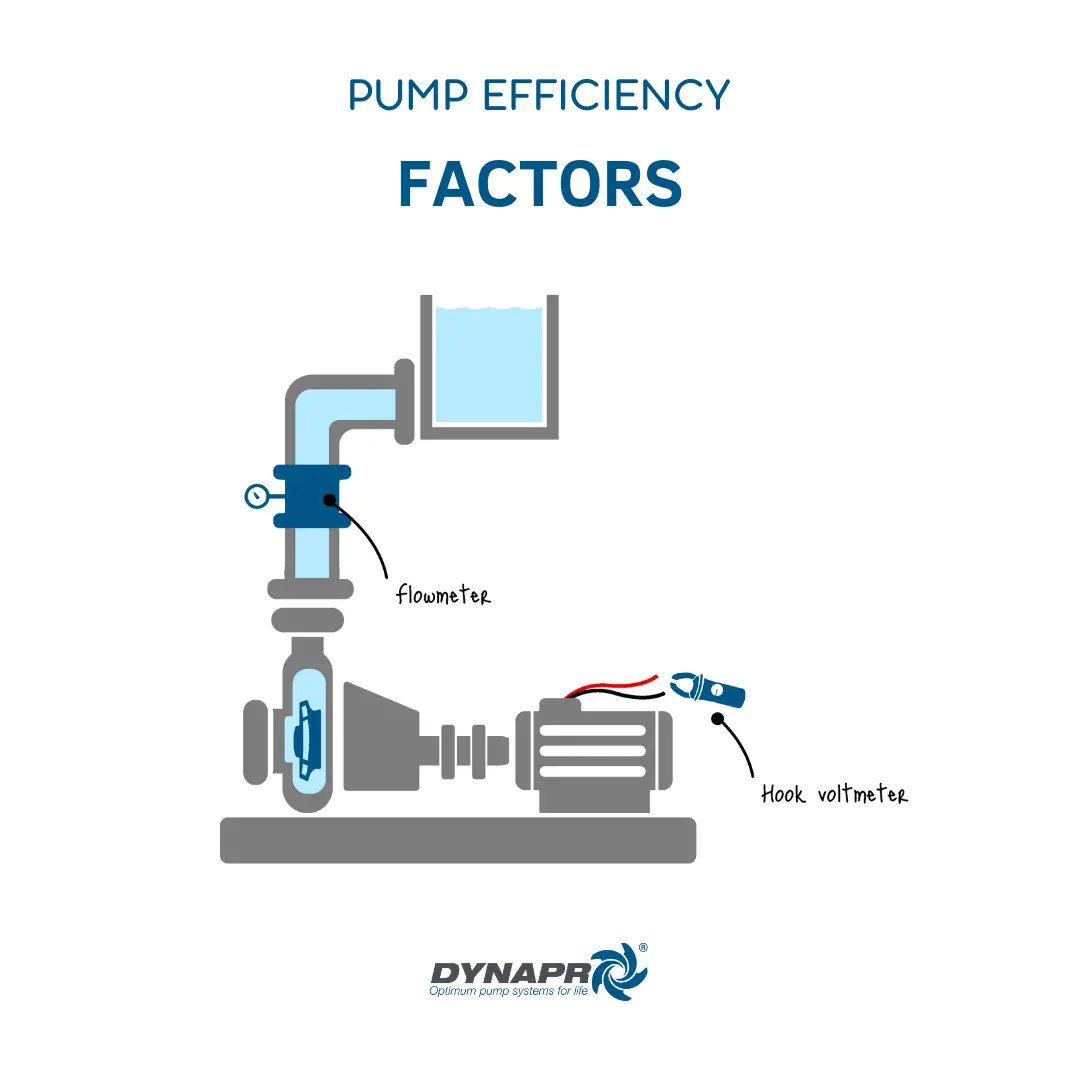

4. Measuring Pump Efficiency

Accurately measuring pump efficiency is crucial in assessing the performance of centrifugal pumps. This entails a thorough evaluation of input and output metrics, including flow rate, total head, power consumption, and hydraulic efficiency, to gain a comprehensive understanding.

Precise measurements and detailed analysis help identify inefficiencies and optimization opportunities, ultimately contributing to cost-effective and sustainable pump operations.

4.1 Calculating Overall Efficiency

Calculating the overall efficiency of a pump involves assessing multiple contributing factors.

- Determine Input Power (Ps): Measure the brake horsepower (BHP) provided to the pump's shaft.

- Measure Output Power (Pw): Calculate the water power using the formula: Pw = (Flow x Head) / 3960.

- Compute Efficiency (Ef): Use the formula Ef = Pw / Ps to determine the pump’s overall efficiency.

Precise measurements of flow, head, and horsepower are essential for accurate efficiency calculations.

Utilizing these calculations helps pinpoint areas where pump performance can be optimized.

4.2 Water Power vs. Shaft Power

Understanding the distinction between water power and shaft power is crucial.

Water power (Pw) refers to the useful hydraulic power the pump delivers to the fluid, calculated using flow rate and head. The formula Pw = (Flow x Head) / 3960 standardizes this calculation into brake horsepower (BHP). Conversely, shaft power (Ps) represents the actual mechanical power supplied to the pump’s shaft.

Calculating Pw and Ps involves precision.

While water power measures the effective work the fluid performs—important for assessing hydraulic efficiency—shaft power quantifies the total input. This metric is vital for evaluating the pump’s combined mechanical and hydraulic efficiencies.

To maximize pump efficiency, understanding these two power metrics is indispensable. By accurately measuring and comparing water power and shaft power, engineers can effectively identify performance gaps, assess potential improvements, and enhance overall pump operations. Such efforts contribute to significant energy savings and improved operational sustainability.

5. Enhancing Pump Efficiency

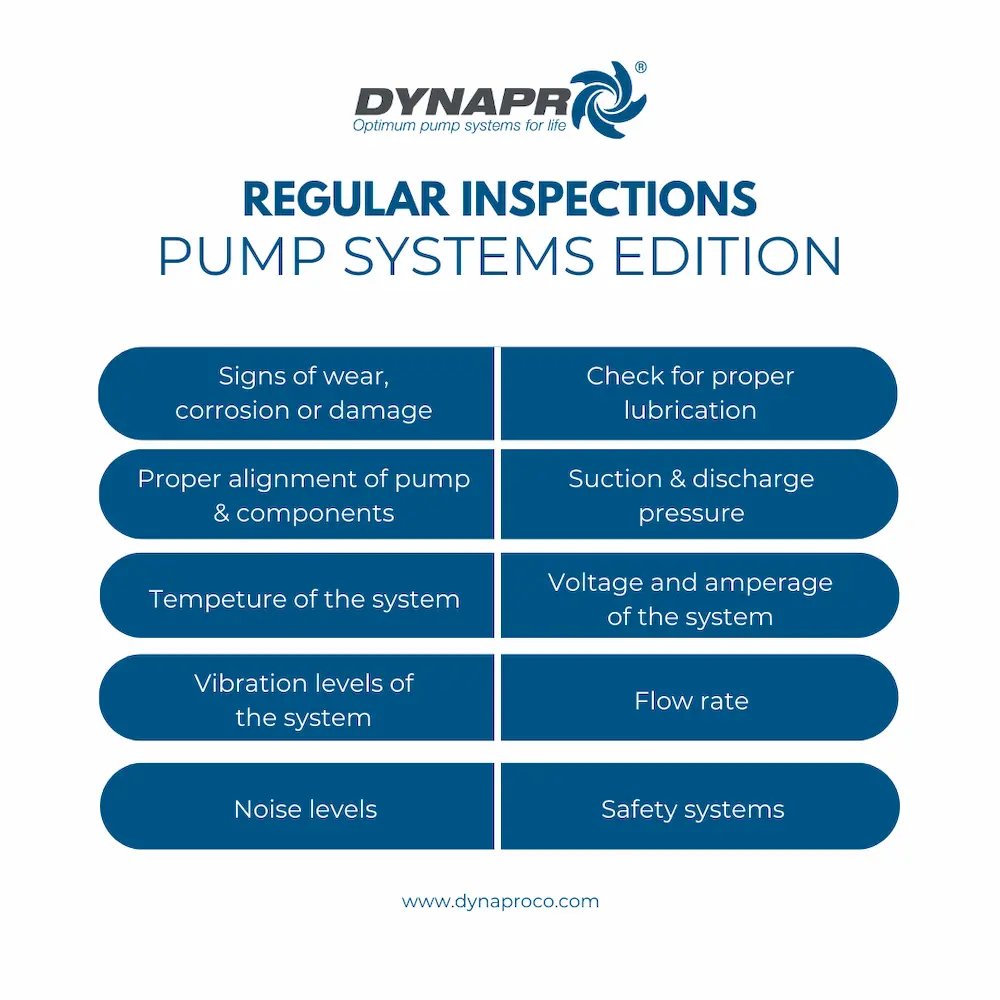

Enhancing pump efficiency transcends mere design optimization; a holistic approach encompassing regular pump maintenance, operational adjustments, and technological upgrades proves vital. Continuous monitoring allows operators to catch inefficiencies early, facilitating timely corrective measures. Implementing variable frequency drives (VFDs), for instance, fine-tunes pump speed to match demand, thus preventing overconsumption of energy. Furthermore, deploying condition-monitoring systems provides real-time data analysis, leading to proactive maintenance strategies and extending pump lifespan. By fostering a culture of efficiency, organizations can achieve considerable energy conservation, cost reduction, and sustainability objectives.

5.1 Adjusting Impeller Speed vs. Diameter

Altering impeller speed instead of diameter preserves pump efficiency, minimizes cavitation, and enhances operational flexibility.

- Retains hydraulic efficiency

- Prevents excessive recirculation

- Allows for precise flow control

- Maintains Best Efficiency Point (BEP) performance over broader ranges

- Supports continuous system adaptability

Speed adjustments provide better control and reduced energy costs.

Reducing impeller diameter can significantly decrease efficiency.

Consider VFDs or other speed modification techniques for optimal results.

5.2 Importance of Peak Efficiency

Peak efficiency in centrifugal pumps plays a crucial role in optimizing overall performance. When a pump operates at its peak efficiency, it utilizes the least amount of energy to perform a given task. This optimized energy usage not only reduces operational costs but also minimizes wear and tear on the pump components, thereby extending the lifespan of the equipment.

However, focusing solely on peak efficiency may not always be practical. Pumps rarely operate continuously at their best efficiency points (BEP). In many real-world applications, pumps experience varying flow demands and head conditions, which means that remaining within a specific efficiency range is often more advantageous than focusing strictly on peak efficiency.

It is essential to consider the breadth of high-efficiency performance. Pumps that maintain higher efficiency over a broader operational range offer more flexibility and reliability in dynamic systems. This versatility is particularly important in applications where flow requirements fluctuate significantly over time.

Ultimately, the importance of peak efficiency needs to be balanced with the need for consistent performance across varying conditions. While peak efficiency offers the lowest operational costs at a specific point, a pump that exhibits a wide range of high efficiency ensures dependable and cost-effective performance under different operational scenarios. This comprehensive approach to efficiency maximizes both immediate and long-term benefits for any application.

5.3 Evaluating Efficiency Across Flow Ranges

Selecting a pump solely based on peak efficiency can be misleading. Why is evaluating efficiency across flow ranges more beneficial?

In 2023, industry professionals emphasize the significance of pumps maintaining high efficiency over diverse flow rates. Fluctuations in demand and variations in head conditions often require this flexibility.

Interestingly, pumps that offer a broad range of high efficiency are more adaptable to real-world conditions. This adaptability enhances overall system performance and reliability.

When comparing pumps, examine their efficiency curves to ensure they maintain high performance across the expected flow variations. This ensures optimal operation and reduced energy costs.

Evaluating efficiency across flow ranges provides a comprehensive view of performance and potential savings.

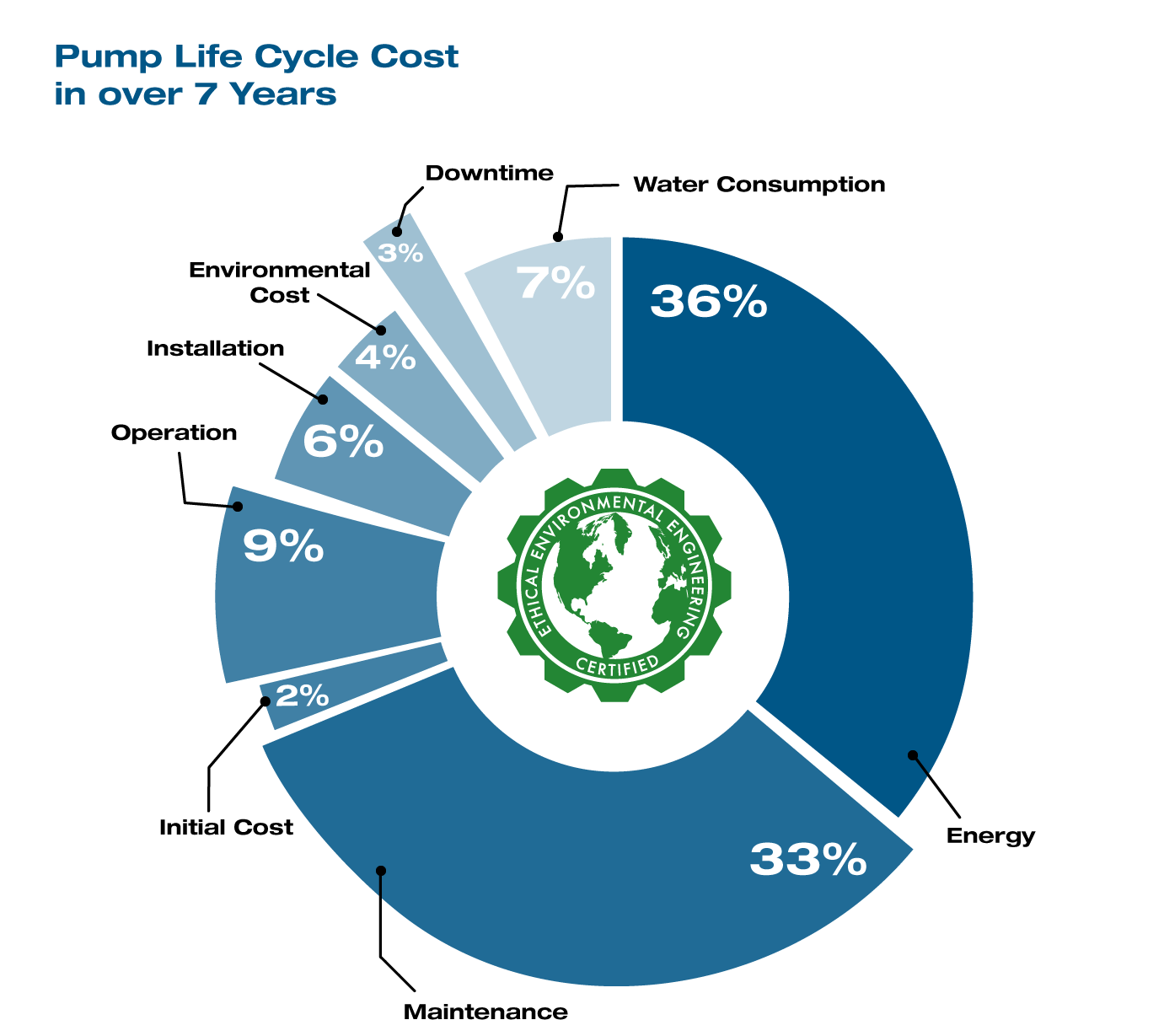

6. Economic Impact of Efficiency

The economic impact of pump efficiency cannot be overstated. When efficiency is maximized, the return on investment manifests not only in the form of reduced operational costs but also through prolonged equipment life and decreased maintenance expenditures.

Higher efficiency equates to substantial savings, especially in energy-intensive applications where even a marginal improvement translates into significant financial gains.

6.1 Cost Savings Through Efficiency

Optimal pump efficiency leads to significant cost savings by reducing energy consumption and operational expenses. When pumps operate efficiently, they convert a greater portion of energy inputs into useful work, minimizing waste and maximizing output.

In applications where pumps run continuously or for extended periods, small improvements in efficiency can lead to substantial reductions in energy costs. For instance, increasing a pump's efficiency from 84 percent to 87 percent could save considerable amounts in annual electricity expenses.

Additionally, high-efficiency pumps often require less frequent maintenance, contributing to lower overall maintenance costs. This is because the reduced strain on pump components results in a longer lifespan and fewer mechanical failures, further enhancing cost savings.

Moreover, efficient pumps can contribute to a smaller carbon footprint, demonstrating environmental responsibility while saving on potential regulatory costs related to emissions and energy use. This aligns business operations with sustainable practices, benefiting both the bottom line and the environment.

In summary, investing in efficient pumps offers compelling economic benefits that extend beyond mere energy savings.

6.2 Electricity Cost Variations

Electricity costs can significantly impact the economic evaluation of pump efficiency improvements. How do these variations affect the decision-making process in different regions?

In 2010, electricity costs varied widely across the United States, ranging from 4 cents per kilowatt-hour in parts of Washington to nearly 40 cents on some Hawaiian islands. This wide range underscores the importance of considering local energy prices when calculating potential savings from increased efficiency.

As energy costs continue to fluctuate, regions with higher rates tend to see more substantial savings from efficiency improvements. This variance in cost can make upgrades in pump efficiency more attractive in certain areas. It also means that a one-size-fits-all approach to pump efficiency may not be feasible.

For instance, in high-cost energy areas, even a small increase in pump efficiency can justify a sizable initial investment due to the rapid payback period. Conversely, in regions with lower energy costs, the economic benefit, while still positive, might be less pronounced, affecting investment decisions.

Ultimately, electricity cost variations play a critical role in determining the financial viability of pump efficiency upgrades across different locales.

7. When Efficiency Is Less Critical

There are situations where pump efficiency, although important, takes a back seat to other considerations. Pumps that are infrequently used, serve as backups, or are employed in certain specialized applications often fall into this category.

In scenarios such as these, the priority shifts to reliability and durability rather than optimum efficiency. For example, in industrial slurry pumping, wider clearances can extend a pump's lifespan, while in wastewater applications, vortex pumps are valued for their obstruction-free operation, despite lower efficiency. Thus, the operational requirements sometimes outweigh the benefits of peak efficiency.

7.1 Industrial Applications with Lower Priority

In the realm of industrial operations, not all applications demand peak pump efficiency.

Infrequently used pumps or those serving as backups often prioritize reliability and longevity over optimum efficiency. For example, smaller pumps designed for minimal operational hours may not justify the higher investment in extremely efficient models.

Pumps used in emergency situations also fall under this category, where the urgency of dependable operation outweighs efficiency considerations. Here, ensuring that the pump performs when needed is far more critical than achieving high efficiency.

Moreover, certain industrial processes, like slurry pumping or wastewater management, involve pumps that operate under harsh conditions, where cavitation and efficiency are secondary to robustness and low-maintenance features.

In such cases, the added cost of an efficient pump may not provide a worthwhile return on investment.

7.2 Types of Pumps with Lower Efficiency Needs

Not all industrial applications necessitate high-efficiency pumps, especially those involving adverse conditions or intermittent use.

Certain pump types, such as slurry pumps and vortex pumps, are specifically designed to endure rugged environments.

These pumps prioritize factors like durability and minimal pump maintenance, as opposed to maximizing efficiency. For instance, vortex pumps, often used in wastewater management, offer lower efficiency but provide unmatched reliability in handling solids and debris.

The initial cost savings and reduced maintenance requirements of such pumps make them an ideal choice for applications where maximizing efficiency would not yield significant benefits. In sum, selecting the right pump often involves balancing efficiency, reliability, and the specifics of the operational environment.

8. Curve Shapes and Efficiency Breadth

Determining the shape of a pump's performance curve can reveal critical insights into an application’s efficiency and adaptability.

As specific speed (Ns) increases, the pump's performance curve transforms, becoming steeper and indicating a greater increase in head near shut-off conditions. This adaptation is paramount in applications requiring variable head conditions.

In contrast, pumps with more extensive efficiency breadth allow greater operational flexibility by maintaining near-peak efficiency across a wider range of flow rates.

8.1 Specific Speed and Curve Shape

Specific speed (Ns) significantly influences performance curves.

In the realm of pump performance, specific speed serves as a critical design determinant. As the specific speed increases, the shape of the performance curve transforms correspondingly. Lower specific speeds typically generate flatter curves, offering smoother performance across a broad range of operations. Conversely, higher specific speeds often produce steeper curves, which can be advantageous in certain high-head applications.

Curve shapes define operational behavior.

The most remarkable aspect of the relationship between specific speed and curve shape is the adaptability it offers. For pumps operating at different specific speeds, understanding this relationship allows for more precise design and selection, optimizing both efficiency and application suitability.

Ultimately, the nuanced relationship between specific speed and curve shape drives informed pump selection. By comprehensively understanding this dynamic, engineers and pump designers can achieve both peak performance and efficiency. This targeted approach ensures pumps are not only energy-efficient but also finely tuned to their intended applications.

8.2 Importance of Efficiency Breadth

Efficiency breadth is crucial for overall operation.

When it comes to pump performance, the importance of maintaining a wide range of high efficiency cannot be overstated. This allows the pump to operate effectively even when deviating from its Best Efficiency Point (BEP), thus accommodating fluctuations and system changes with minimal loss in performance.

Maintaining efficiency across varied rates minimizes energy waste.

This aspect becomes particularly valuable in applications where demand may vary—that is, where the pump must handle different flow rates efficiently. Systems facing such variable conditions can achieve consistent performance and energy savings over time.

Additionally, broader efficiency ranges contribute to operational reliability. Pumps that maintain higher efficiency over a flexible range of conditions are less prone to overheating and excessive wear, thus extending their operational longevity and reducing maintenance costs.

9. Effects of Impeller Trim

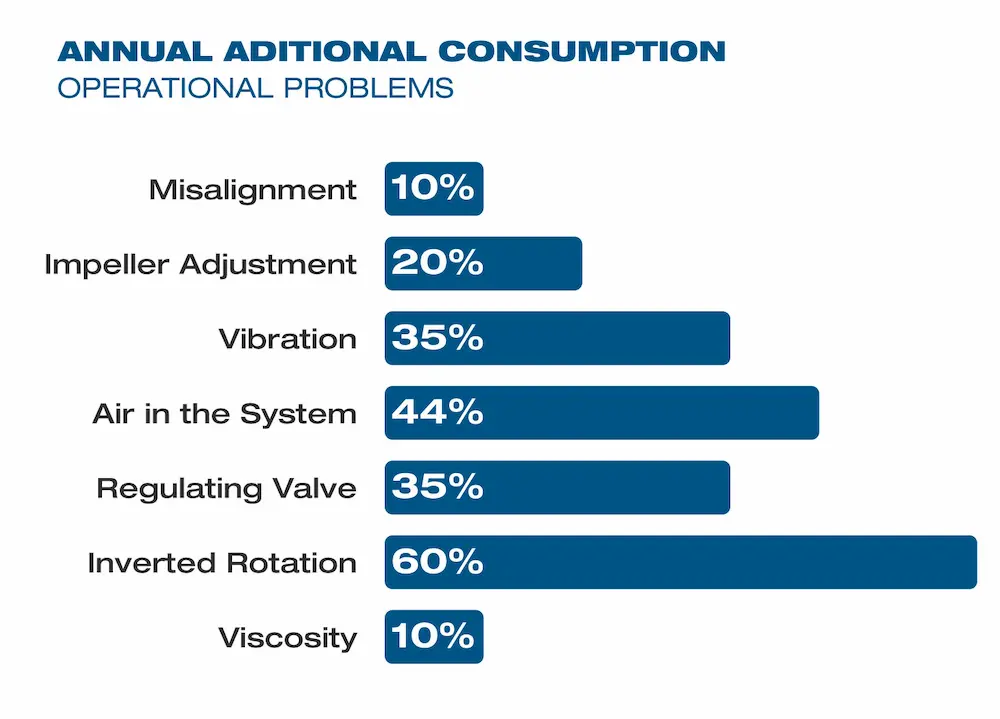

Trimming the impeller's diameter impacts the pump’s hydraulic efficiency, primarily by altering the peripheral speed and tongue clearance. As the impeller is trimmed, recirculation within the pump increases, which leads to a decline in overall efficiency.

For example, a pump with an impeller trimmed by 11% may see efficiency drop from 77% to 74%. Further trimming can exacerbate this effect, with reductions of up to 33% leading to efficiency plummeting to 62%. Therefore, significant trimming is generally inadvisable unless absolutely necessary. Instead, altering impeller speed can be a more effective solution to maintain optimal efficiency.

9.1 Depth of Trim Impact

Efficiency significantly decreases with increased trim.

Understanding the depth of trim impact is critical for achieving optimal pump performance. Each incremental reduction in the impeller's diameter magnifies the efficiency loss due to heightened recirculation, making it crucial to assess the necessity of each trim. Practically, this means decisions should prioritize maintaining as close to full impeller diameter as feasible.

Trim adjustments should be cautiously executed.

Adjustments should ideally not exceed 10% to safeguard efficiency. Beyond this threshold, the hydraulic performance suffers substantially, underscoring the importance of precise engineering evaluations before making such modifications.

Proper assessment can save energy and reduce costs. Inefficient pumps that undergo excessive trimming lead to higher operational expenses and increased maintenance requirements, underscoring the need for strategic planning and execution in pump design and alterations.

9.2 Managing Efficiency Loss

Efficiency management requires vigilant monitoring.

Pump operators must recognize the vital importance of maintaining near-peak efficiency. Any deviations, however slight, can lead to significant increases in operational costs and potential system failures. Consequently, a balance needs to be maintained between pump performance and routine system checks to mitigate efficiency loss effectively.

Routine assessments can identify inefficiencies.

Advanced diagnostic tools and regular performance evaluations should be employed. These practices help in proactively addressing minor issues before they exacerbate.

Proper maintenance extends pump life.

Integrating predictive maintenance strategies not only preserves efficiency but also prolongs the lifespan of pumping equipment. Using real-time analytics, operators can foresee potential problems and schedule timely interventions, thus maintaining optimal performance.

Operators should be trained in efficiency awareness. Investing in continuous professional development ensures that the workforce is adept at identifying and managing efficiency losses. This two-pronged approach of technology and training constitutes a robust defense against the gradual degradation of pump efficiency, thereby fostering long-term sustainability and cost-effectiveness.

10. Speed Alteration for Efficiency

Speed alteration stands as a powerful strategy, especially in maximizing pump efficiency. Variable Frequency Drives (VFDs) allow operators to modify the pump speed, thereby optimizing efficiency without the need for mechanical changes.

Each alteration must be carefully evaluated to match the operational requirements. Choosing to alter speed rather than trim the impeller ensures that the pump operates within its designed optimal efficiency. This nuanced approach maintains hydraulic efficacy and minimizes energy waste, leading to significant cost savings in the long run.

10.1 Using Variable Speed Drives

Utilizing variable speed drives (VSDs) offers a dynamic approach to enhancing pump efficiency. By adjusting pump speeds electronically, operators attain precise control over the pump's performance parameters.

This utility is beneficial for managing diverse operational conditions. VSDs can adapt to varying demands without necessitating mechanical alterations.

Through this method, energy savings are maximized. Consistent operational efficiency is maintained as VSDs enable optimal pump performance at all times.

Moreover, reducing mechanical wear and tear leads to longer pump life. Consequently, maintenance costs are minimized, further amplifying the benefits of VSDs.

This precision control technology is indispensable for maintaining peak operational efficiency. Efficient speed management ensures sustainable and cost-effective pump operation.

Hence, the integration of VSDs is paramount in modern pump systems. This technological advancement plays a critical role in optimizing energy efficiency and operational longevity.

10.2 Belt Drives and Adjustments

When considering belt drives, optimizing pump efficiency requires careful alignment and tension adjustments.

These adjustments, in precise increments, allow for a controlled rotational speed of the pump impeller, ensuring the transmitted power from the motor is maximized effectively. Furthermore, maintaining proper belt tension reduces slippage and thus enhances the mechanical efficiency of the system.

Additionally, belts allow for a convenient mechanism to adjust speeds. By selecting appropriate pulley sizes, operators can fine-tune the pump's rotational speed almost as efficiently as more sophisticated electronic methods.

When incorporated, these mechanical adjustments provide a resilient and economically feasible solution, particularly for applications where electronic drives may be impractical or cost-prohibitive. Regular maintenance checks and tension adjustments ensure that belt-driven systems operate with optimal efficiency, prolonging equipment life and reducing overall operational costs.

FREQUENTLY ASKED QUESTIONS

How do you calculate pump efficiency?

Calculating pump efficiency involves understanding the interplay between input power and output power. For centrifugal pumps, efficiency (Ef) is the ratio of the mechanical power supplied to the pump shaft (Ps) to the hydraulic power (Pw) delivered to the fluid.

To approximate pump efficiency, one must calculate the water power, which is determined using the formula: Pw = (Q x H) / 3960. Here, Pw represents water power in brake horsepower (BHP), Q signifies flow rate in gallons per minute (GPM), and H denotes head in feet. The constant 3960 converts these parameters to BHP.

Next, the shaft power (Ps) must be measured. This is the power needed by the pump shaft to handle the hydraulic power requirements. Typically, Ps is provided in terms of BHP. An accurate measure of shaft power ensures the pump operates at its expected efficiency level.

Finally, calculate the pump efficiency using the equation: Ef = Pw / Ps. This ratio, often expressed as a percentage, can guide decisions regarding energy consumption, cost optimization, and system performance. By closely analyzing these calculations, professionals can identify potential improvements and implement strategic changes to enhance overall pump efficiency.

Why are pumps not 100% efficient?

No pump can achieve 100% efficiency due to inherent mechanical losses within its components. These include frictional losses in bearings and seals, which reduce the overall mechanical efficiency of the pump system.

Leakage across components reduces the volumetric efficiency. Leakage through wear rings and balancing holes contributes to inefficiencies that cannot be entirely eliminated.

Hydraulic losses further diminish pump efficiency. Turbulence and fluid friction within the impeller and volute cause energy dissipation that is unavoidable in practical designs.

Energy conversion is never perfect due to fundamental thermodynamic principles. Converting mechanical energy into hydraulic energy inevitably leads to heat loss and other inefficiencies.

Manufacturing limitations also play a role. Even the most precisely engineered components cannot be made perfectly smooth or perfectly aligned, leading to minor, yet impactful, efficiency losses.

In conclusion, while extraordinary precision in design and manufacturing can optimize efficiency, reaching 100% efficiency remains unattainable. Balancing efficiency with reliable performance and acceptable costs remains the ultimate goal in pump design and engineering.

What is the overall efficiency of the pump?

Pump efficiency measures how effectively a pump converts input energy into hydraulic output. This conversion is critical in determining the pump's performance and overall cost-effectiveness.

In essence, the overall efficiency of a centrifugal pump is derived from three components: mechanical, volumetric, and hydraulic efficiency. Mechanical efficiency includes losses within the bearing frame and seals, while volumetric efficiency accounts for leakage issues. Hydraulic efficiency, influenced by liquid friction and internal recirculation, often has the most significant impact.

The efficiency of individual components directly affects the pump's effectiveness. For example, losses due to leakage through wear rings and balancing holes reduce volumetric efficiency. In contrast, hydraulic losses in the volute and impeller can significantly affect hydraulic efficiency, which is critical for optimal pump operation.

A pump's efficiency can be represented by a simple equation: Ef = Pw / Ps, where Pw stands for the water power and Ps indicates the shaft power. Together, these factors offer a quantifiable measure of how efficiently a pump operates at any given point.

Improving pump efficiency involves careful consideration of design, operational speeds, and maintenance protocols. By focusing on these aspects, engineers can ensure that pumps operate at peak efficiency, leading to reduced energy consumption and lower operational costs.

What is the most efficient pump available?

Determining the most efficient pump available depends on the specific application and operating conditions. Generally, large centrifugal pumps and AC induction motors are among the most efficient. Medium to large centrifugal pumps often achieve efficiencies between 75 to 93 percent, while large AC motors can approach 97 percent efficiency. For applications requiring high efficiency, selecting a pump and motor combination that operates close to their Best Efficiency Point (BEP) is crucial. Additionally, modern advancements in pump design and materials continue to push the boundaries of efficiency, making it essential to consult with manufacturers and review the latest specifications for the most up-to-date information.

Definitions of Terms Related to Pump Efficiency

- Pump Efficiency (Ef): The ratio of the water (output) power to the shaft (input) power of a pump.

- Water Power (Pw): The hydraulic power output of a pump, calculated as ( Pw = \frac{Q \times H}{3960} ), where ( Q ) is the flow rate in gallons per minute (GPM) and ( H ) is the head in feet.

- Shaft Power (Ps): The mechanical power input to the pump shaft, typically measured in brake horsepower (BHP).

- Mechanical Efficiency: The efficiency related to losses in the bearing frame, stuffing box, and mechanical seals.

- Volumetric Efficiency: The efficiency accounting for losses due to leakage through wear rings, balancing holes, and vane clearances in semi-open impellers.

- Hydraulic Efficiency: The efficiency considering liquid friction and other losses within the volute and impeller.

- Specific Speed (Ns): A dimensionless number that describes the geometry of a pump impeller and predicts its performance, particularly the shape of the pump’s performance curve.

- Best Efficiency Point (BEP): The flow rate at which a pump operates at its highest efficiency.

- Brake Horsepower (BHP): The actual horsepower delivered to the pump shaft.

- Affinity Laws: Mathematical relationships that describe how changes in speed or impeller diameter affect the flow, head, and power of a pump.

- Peripheral Velocity: The speed at the outer edge of the impeller, which determines the maximum head and flow attainable.

- Head (H): The height to which a pump can raise water, typically measured in feet.

- Flow Rate (Q): The volume of fluid that a pump can move, typically measured in gallons per minute (GPM).

- Variable Frequency Drive (VFD): A device that controls the speed of an electric motor by varying the frequency of the electrical power supplied to it, used to optimize pump efficiency.

- Trimmed Impeller: An impeller that has been reduced in diameter to match specific operating conditions, which can affect the pump’s efficiency.

- Recirculation: The flow of fluid back into the pump casing, which can reduce hydraulic efficiency.