NPSH Explained: Simple Guide for Pump Beginners

Oct 18, 2025

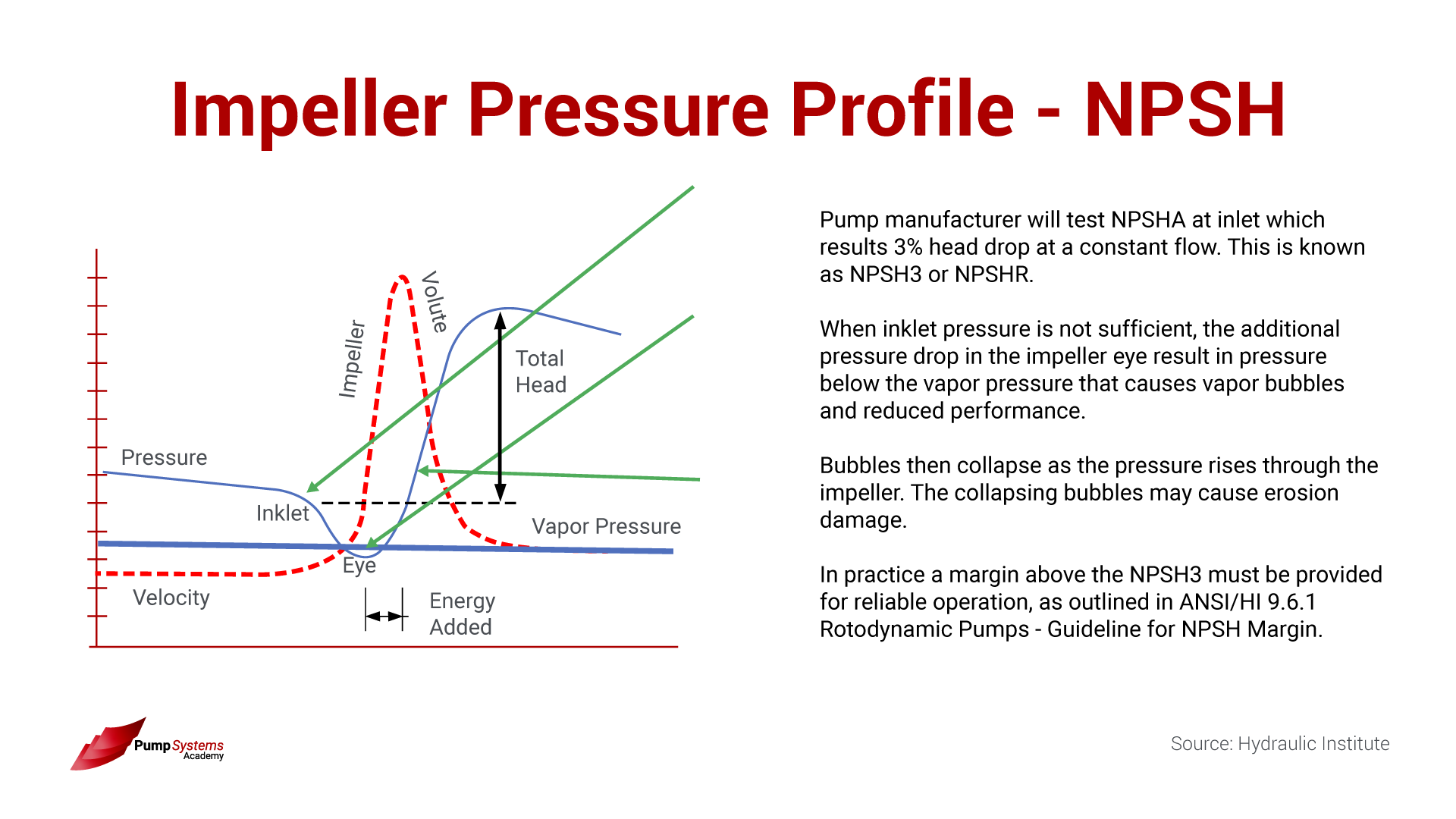

Every centrifugal pump student hears about cavitation early, yet the path back to root causes often loops through one concept: NPSH. Here is npsh explained in practical terms, with the minimum math needed to size, select, and troubleshoot. The goal is simple. Keep suction pressure high enough above the liquid’s vapor pressure so it stays liquid as it enters the impeller eye. When that margin collapses, bubbles form and the pump’s day goes badly.

The sections below clarify vocabulary, separate system facts from pump facts, and provide a calculation method and field tips that hold up under real operating conditions.

What Is NPSH

Net Positive Suction Head is the absolute pressure head at the pump suction above the fluid’s vapor pressure. It measures how far the inlet conditions are from boiling. Head units are used rather than pressure because head is independent of fluid density when expressing energy per unit weight. Engineers typically work in meters or feet of the pumped liquid.

A few points settle most confusion:

- NPSH is based on absolute pressure, not gauge.

- The lowest local pressure is at or near the impeller eye; that is where vapor bubbles first appear if inlet energy is inadequate.

- Vapor pressure depends on temperature, so the same system can be fine when cold and problematic when hot.

Why it matters is easy to see in the field. If NPSH is inadequate, vapor bubbles form, then collapse as they move to higher-pressure regions inside the pump. The collapse sends shock waves into metal surfaces, which leads to noise, vibration, impeller pitting, seal distress, and falling performance. Protecting the inlet pressure margin protects the machine.

NPSH Explained: NPSHa vs NPSHr (Key Differences)

Two acronyms carry the whole topic:

- NPSHa: available from the system at the suction flange. Depends on barometric pressure, tank pressure, elevation difference, friction losses, and fluid temperature.

- NPSHr: required by the pump to operate without cavitation at a given flow and speed. Comes from the manufacturer’s test curve.

A quick comparison helps during selection and troubleshooting.

|

Item |

NPSHa (Available) |

NPSHr (Required) |

|---|---|---|

|

Who sets it |

Piping and vessel conditions |

Pump design and test |

|

Where to find it |

Calculate or measure |

|

|

Changes with |

Level, temperature, altitude, pipe loss, flow |

Flow rate, speed, impeller geometry |

|

Units |

Head (m or ft) of the pumped liquid |

Head (m or ft) of the pumped liquid |

|

Rule to avoid cavitation |

Keep NPSHa higher than NPSHr by a margin |

Lower is better, but fixed by design at each duty point |

A practical margin is 10 to 30 percent above the published NPSHr at the operating point. Higher speed, higher flow, and small impeller eye designs raise NPSHr, so matching system reality to pump curves is essential.

How to Calculate NPSHa

The standard head balance at the pump suction is:

NPSHa = atmospheric head + static head − vapor pressure head − suction friction losses

Each term requires care:

- Atmospheric head: convert local barometric pressure to head of the pumped liquid. At sea level this is about 10.3 m for water. High-altitude sites have less, stormy days a bit less than clear high-pressure days.

- Static head: elevation difference between liquid surface and pump centerline. Positive for flooded suction, negative for suction lift.

- Vapor pressure head: absolute vapor pressure at the operating temperature converted to head. This grows quickly with temperature.

- Suction friction losses: head loss in the suction pipe, valves, strainers, and fittings at the actual flow.

Absolute vs gauge pressure matters here. If a suction gauge reads near zero psig on an open tank, the absolute pressure at the liquid surface is still one atmosphere and must be included before subtracting vapor pressure.

A short worked example (water service, approximate values):

- Site at sea level: atmospheric head = 10.3 m

- Flooded suction: liquid level 1.5 m above pump centerline, static head = +1.5 m

- Water at 60 C: vapor pressure ≈ 20 kPa → 20,000 Pa ÷ (1000 kg/m³ × 9.81 m/s²) ≈ 2.0 m

- Suction piping: 4 m of head loss at the target flow

NPSHa = 10.3 + 1.5 − 2.0 − 4.0 = 5.8 m

If the pump curve shows NPSHr = 4.8 m at that flow, the margin is 1.0 m (about 21 percent). A warm day, a clogged strainer, or a slightly higher flow could erase that cushion, which is why most plants aim for a healthy buffer.

Key influences to watch:

- Barometric pressure: altitude and weather shift the atmospheric term.

- Suction lift vs flooded suction: every meter of lift subtracts roughly one meter of NPSHa for water.

- Friction losses: velocity squared drives them. Larger suction lines and gentle fittings keep losses low.

- Temperature effect: vapor pressure balloons with temperature, which can remove several meters of head from the budget.

When measuring in the field, use absolute references or add atmospheric pressure to gauge readings. A vacuum gauge on the suction can be helpful, but only if converted correctly. Consistency in units and datum is vital.

Cavitation: Symptoms, Diagnosis, and Prevention

Cavitation has a distinctive personality. Operators and technicians often pick it out by ear before instruments respond.

Common symptoms:

- A sharp, crackling noise that sounds like marbles or gravel in the casing

- Higher vibration, especially broadband content and random spikes

- Reduced discharge pressure and flow compared to the curve at the same speed

- Irregular motor current draw

- Pitting and erosion near the impeller eye after inspection

Diagnosis steps:

- Listen first, then verify with vibration analysis or acoustic probes

- Check suction pressure on an absolute basis and compare to vapor pressure at the measured temperature

- Compare current operating point to the pump curve and NPSHr curve

- Inspect strainers, foot valves, and any throttled suction valves for unexpected loss

- Look for air entrainment: vortexing at the tank, leaking suction gaskets, or gas pockets in high points

Prevention priorities:

- Maintain margin: keep NPSHa above NPSHr with room to spare. If the calculation is tight, raise level, lower the pump, or select a pump with lower NPSHr.

- Control temperature: cooler liquid means lower vapor pressure and higher NPSHa.

- Reduce losses: increase suction pipe size, shorten runs, use long-radius elbows, remove unnecessary fittings, and keep strainers clean. Aim for suction line velocities in the 1 to 2 m/s range for water service.

- Improve inlet hydraulics: provide straight run into the pump, avoid elbows right at the suction flange, and use an eccentric reducer flat on top to prevent air pockets.

- Avoid air entrainment: eliminate leaks, submerge suction nozzles adequately, and use anti-vortex baffles in tanks.

- Choose the right hydraulics: double-suction impellers, inducers, or pumps designed for low NPSHr help when systems cannot supply more head.

- Operate near BEP: running far left or right of the best efficiency point can trigger suction or discharge recirculation, which raises NPSHr and adds vibration. A VFD can hold the duty near BEP across seasons.

Small mechanical changes often give big wins. Raising liquid level by 0.5 to 1 m, upsizing a short suction spool, or removing one unnecessary elbow can restore a safe margin.

FAQ

Q1: Does NPSH use absolute or gauge pressure?

A1: Absolute. Convert any gauge readings by adding atmospheric pressure before subtracting vapor pressure.

Q2: How much margin over NPSHr is advisable?

A2: A common target is 10 to 30 percent above the published NPSHr at the expected flow. More margin is wise for hot liquids or variable conditions.

Q3: Why does temperature affect NPSH so much?

A3: Vapor pressure climbs fast with temperature. Higher vapor pressure subtracts directly from NPSHa, shrinking the inlet pressure cushion.

Q4: What is the difference between suction lift and flooded suction?

A4: Suction lift means the pump is above the liquid level, which subtracts head. Flooded suction means the pump is below the level, which adds head.

Q5: Can operating away from BEP cause cavitation even if NPSHa meets NPSHr?

A5: Yes. Off‑BEP operation can induce recirculation and turbulence that raise the effective NPSHr and promote cavitation. Keeping the duty near BEP lowers risk.

Q6: Do strainers and foot valves affect NPSH?

A6: Yes. Their resistance appears as suction friction loss. Dirty or undersized elements can remove several meters of NPSHa.

Q7: How does altitude change NPSHa?

A7: Higher altitude lowers barometric pressure, which reduces the atmospheric head term. Expect several meters less NPSHa on mountain sites compared to sea level.

Q8: Is NPSHr a single number for a pump?

A8: No. It varies with flow and speed, and is shown on the pump curve. NPSHr usually rises at higher flows.

Q9: What role does air entrainment play?

A9: Entrained air reduces effective density, disrupts inlet flow, and worsens cavitation. Prevent leaks and vortexing, and avoid high points that trap gas.

Q10: Can a VFD help with NPSH issues?

A10: Often yes. Slowing the pump reduces flow, cuts suction friction losses, lowers NPSHr, and may restore a safe margin, while keeping the duty near BEP.