How Net Positive Suction Head Prevents Cavitation

Jul 30, 2025

Understanding net positive suction head (NPSH) is akin to deciphering an intricate dance choreography; each step must be precise and in harmony with the others. Often, the concept baffles even seasoned pump professionals.

With persistence, confusion lingers. Within this article, several terms could be new to you, depending on your level of experience with pump systems. At the bottom of this article is a Glossary of Terms, for your reference.

At The Pump Systems Academy, they tackle this challenge head-on by demystifying NPSH, empowering pump operators and engineers to harness its principles effectively in their daily operations.

Introduction to Centrifugal Pumps

In the world of fluid dynamics, centrifugal pumps stand as a cornerstone of modern mechanics, essential for countless industrial processes.

Their role is to transfer fluids through rotational energy, simplifying various transportation tasks.

These pumps utilize impellers to convert the mechanical energy from a motor into kinetic energy, pushing fluids through a system with force and efficiency.

By understanding the intricacies of centrifugal pumps, individuals can optimize their performance, achieving greater operational efficiency and reliability. As centrifugal pumps are ubiquitous in diverse industries, mastering their functionality is indispensable for anyone committed to excellence in fluid management.

Importance of Net Positive Suction Head (NPSH)

NPSH ensures pump efficiency and longevity.

Understanding NPSH is crucial for maintaining optimal pump performance. The correct calculation and application of NPSH prevent issues such as cavitation, which can lead to significant damage to pump components. Consequently, mastering NPSH not only enhances the efficiency of the pumping system but also extends the equipment's operational life.

This foundational knowledge is indispensable.

Pump operators must be vigilant about NPSH - as its significance cannot be overstated - ensuring that they always have adequate suction conditions to maintain peak pump performance.

Overall, recognizing and applying NPSH principles paves the way for operational excellence. Adhering to these practices reduces downtime, minimizes maintenance costs, and ensures long-term productivity, fostering a more resilient and efficient industrial process.

Defining Net Positive Suction Head

The net positive suction head (NPSH) is a fundamental principle in fluid dynamics. It is crucial to both understanding and optimizing pump performance.

NPSH comprises two key components: NPSH available (NPSHa) and NPSH required (NPSHr), each with distinct roles.

NPSHa represents the energy level available at the pump's impeller eye, while NPSHr indicates the energy required to avoid cavitation. Recognizing the interplay between these elements is essential.

A higher NPSH margin, where NPSHa exceeds NPSHr, ensures the pump operates efficiently and avoids cavitation. This fosters longer equipment lifespan, reduces maintenance costs, and enhances overall system reliability, driving industrial progress and innovation.

Types of NPSH

In the realm of centrifugal pumps, understanding the different types of net positive suction head (NPSH) is paramount for achieving optimum performance. The two primary types, NPSH available (NPSHa) and NPSH required (NPSHr), serve as critical benchmarks to evaluate for ensuring fluid systems operate seamlessly.

NPSHa quantifies the energy level the system can provide, while NPSHr measures the energy needed by the pump to function without cavitation.

NPSH Available (NPSHa)

Net positive suction head available, or NPSHa, represents the liquid energy level at the pump’s impeller eye, crucial for efficient pump operation and preventing cavitation.

It primarily depends upon absolute pressure, static head, vapor pressure, and friction head within the suction system, meticulously tailored for varying industrial setups and conditions.

Insufficient NPSHa can lead to cavitation, causing damage and reducing pump efficiency.

Analyzing NPSHa enables engineers to design systems that account for worst-case scenarios, ensuring reliability even under fluctuating operating conditions. By mastering this concept, they extend pump lifespan, optimizing performance and reducing maintenance costs significantly.

NPSH Required (NPSHr)

NPSH required (NPSHr) represents the minimum energy needed to avoid cavitation and ensure optimal pump performance.

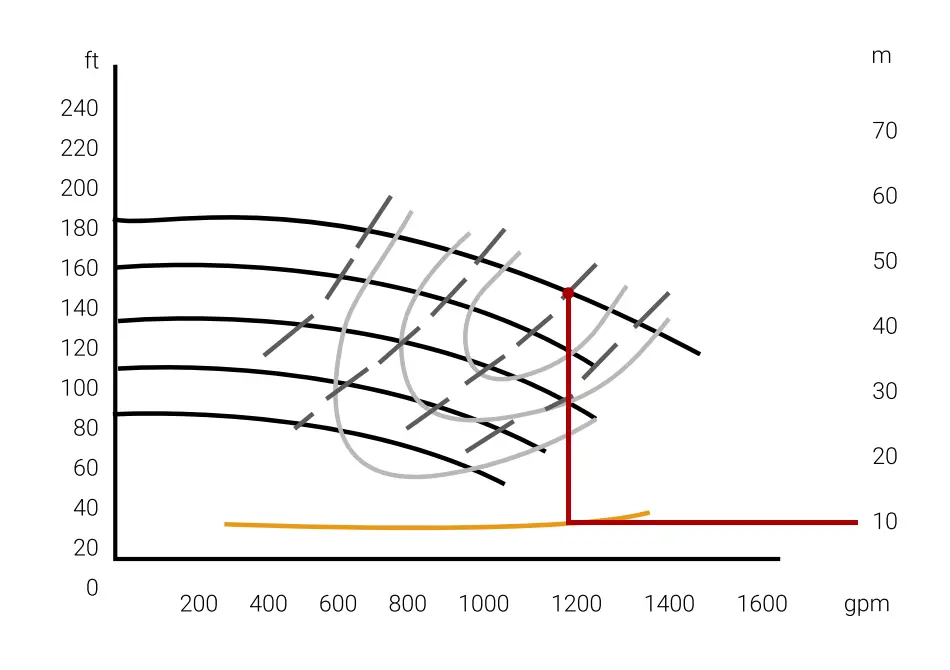

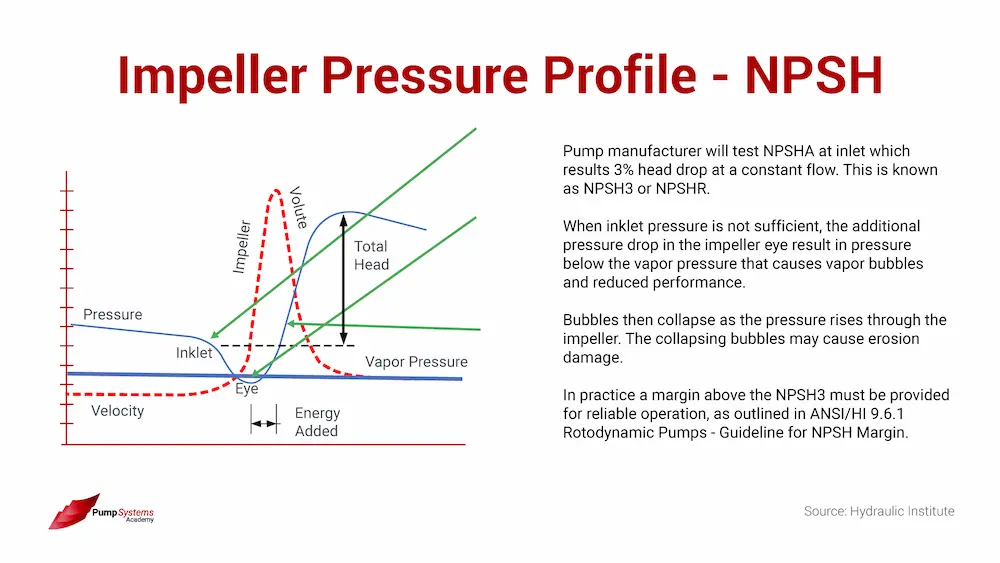

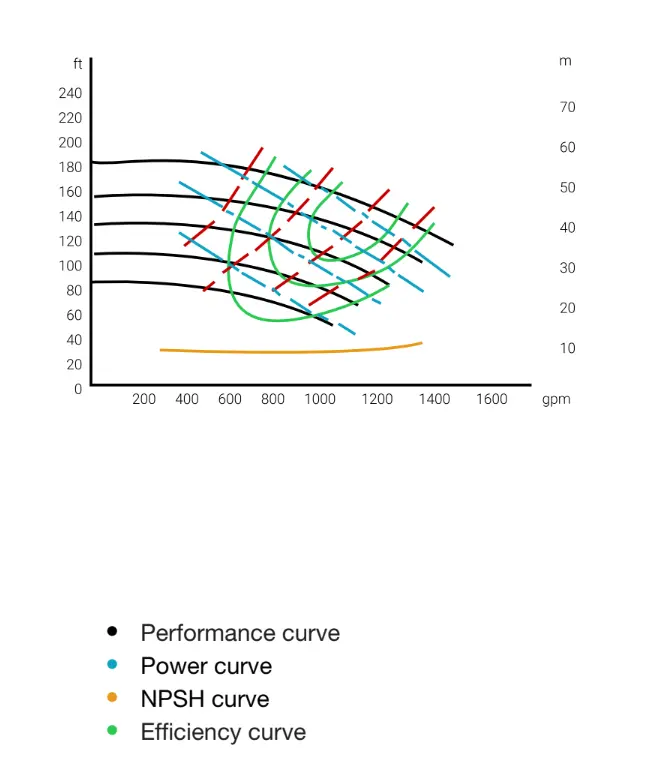

Manufacturers determine this value through empirical methods and standards set by the Hydraulic Institute. NPSHr is often displayed on pump performance curves, indicating the specific conditions at which the pump begins to cavitate. When head drops by 3 percent at a given flow rate and head, this marks the NPSH3 point.

Understanding NPSHr is not just about avoiding damage. It is also about maintaining the integrity of the pumping system, ensuring the pump can operate reliably under the desired conditions without compromise.

A detailed understanding of NPSHr, coupled with a properly calculated NPSHa, empowers professionals to design and implement robust systems. Ensuring the NPSHa exceeds the NPSHr by a healthy margin can safeguard pump operations, leading to increased efficiency and reduced risk of unexpected failures, thereby delivering sustainable and dependable fluid handling solutions.

Calculating NPSH for Centrifugal Pumps

Calculating NPSH for centrifugal pumps involves understanding both NPSHa and NPSHr.

To calculate NPSHa, one must consider absolute pressure, static head, vapor pressure, and friction head. Accurate calculations ensure the pump has sufficient energy to avoid cavitation and maintain optimal function.

The equation for NPSHa is:

[ \text{NPSHa} = h_a + h_{st} - h_{vpa} - h_f ]

Where:

- ( h_a ) = Absolute pressure on or at the liquid surface (in feet)

- ( h_{st} ) = Static head (vertical distance from the top of the water surface to the pump impeller eye, in feet)

- ( h_{vpa} ) = Vapor pressure of the liquid (in feet)

- ( h_f ) = Friction head (in feet)

Elevation above sea level affects NPSH by altering the atmospheric pressure acting on the liquid surface. As elevation increases, atmospheric pressure decreases, which in turn reduces the absolute pressure component (( h_a )) in the NPSHa equation. This reduction in absolute pressure lowers the NPSHa value, making it more challenging to prevent cavitation. Therefore, systems operating at higher elevations require careful consideration and potentially additional measures to ensure sufficient NPSHa is maintained.

With regard to NPSHr, this value is often obtained through empirical testing and is provided in pump performance curves. It defines the minimum suction head required to prevent cavitation at specific flow rates and head conditions.

The equation for NPSHr is:

[ \text{NPSHr} = \text{NPSH required by the pump} ]

Where:

- ( \text{NPSHr} ) = Net Positive Suction Head required by the pump to avoid cavitation, typically determined through empirical methods and provided by the pump manufacturer.

A clear comprehension of both NPSHa and NPSHr allows for effective pump system designs. Ensuring NPSHa consistently exceeds NPSHr not only enhances efficiency but also guarantees reliability and longevity in pump operations.

NPSH and Cavitation Prevention

NPSH plays a critical role in safeguarding pumps from the damaging effects of cavitation. Cavitation occurs when the pressure of the liquid at the pump inlet drops below its vapor pressure, causing the liquid to vaporize and form bubbles.

These bubbles can implode and damage the pump components. Ensuring the NPSHa is adequately higher than the NPSHr can prevent this.

Maintaining an ample NPSH margin is essential for ensuring uninterrupted pump performance. Operators should strive to maximize this margin through careful attention to system design, ambient conditions, and fluid properties.

By taking proactive measures, professionals can mitigate the risk of cavitation, thus extending the lifespan of pump systems and reducing maintenance costs. A well-designed pump operation, featuring a sufficient NPSH margin, contributes significantly to overall operational efficiency and reliability.

Factors Affecting NPSH

Understanding the factors influencing net positive suction head (NPSH) is essential for ensuring optimal pump performance and longevity.

One key component is absolute pressure at the liquid surface.

Ambient pressure changes, such as those caused by high elevations, can significantly impact NPSH.

Additionally, temperature variations affect the vapor pressure of the liquid, thereby altering the NPSH available.

Friction losses within the piping system also play a critical role, with poor design or maintenance increasing these losses.

Finally, the configuration of the suction system, whether flooded or in lift conditions, dictates the resultant NPSH. Accurate assessments of these factors are crucial for maintaining efficient pump operations.

Common NPSH Calculation Methods

Several critical steps are involved in calculating net positive suction head accurately. Essential components include absolute pressure, static head, vapor pressure, and friction losses, all measured in feet, with velocity head often considered negligible.

These calculation methods enable engineers to design systems that achieve optimal pump performance. Utilizing reliable reference materials and understanding each variable's impact ensure accurate NPSH assessments.

Hydraulic Institute Method

The Hydraulic Institute Method provides standardized guidelines.

These guidelines serve to align the measurements of NPSH required (NPSHr). They focus the analysis on accurately determining the suction conditions, ensuring pumps are designed to handle various applications effectively. Primarily, this method emphasizes empirical testing and performance curves to derive NPSHr values.

NPSHr values are crucial benchmarks.

By adhering to the standards dictated by the Hydraulic Institute, industry professionals mitigate the risks associated with inadequate NPSH. This approach ensures that pumps operate reliably without undue cavitation, thereby extending their operational lifespan.

The latest updates to these guidelines, as of their 2023 revision, signify the Hydraulic Institute’s dedication to reflecting ongoing advancements. Engineers and pump designers relying on these updated standards can expect enhanced precision and reliability in their NPSH evaluations.

Field Test Method

Field tests provide crucial insights, allowing for accurate measurement and validation of NPSH values.

In industry applications, it is often necessary to verify NPSHa directly on site. This involves installing temporary instrumentation to measure pressure, temperature, and flow rates under actual operating conditions. These tests help identify any discrepancies between theoretical calculations and real-world performance, ensuring the system's reliability and efficiency.

Accurate field data allows for a comprehensive assessment of the suction system. By comparing these values with the pump manufacturer’s NPSHr data, engineers can determine if the pump operates within safe margins. This pragmatic approach mitigates the risk of cavitation and other performance issues.

Performing field tests under various operating conditions is imperative for a holistic analysis. Seasonal variations, load changes, and other dynamic factors are accounted for, providing a robust evaluation of the pump’s capability. This practical method underscores the importance of adaptability and precision in maintaining optimal pump performance and longevity.

Tools and Instruments for Measuring NPSH

What tools and instruments are essential for accurately measuring the net positive suction head (NPSH)?

The right equipment directly correlates with a system's precision. Pressure transducers, flow meters, and temperature sensors are central to obtaining accurate data critical for evaluating NPSH values accurately.

Among the arsenal of these invaluable tools, pressure gauges stand as a primary reference. These gauges measure the absolute pressure at the pump's suction side against atmospheric pressure, delivering accurate readings imperative for NPSH calculations.

Complemented by state-of-the-art data acquisition systems, real-time monitoring has never been more accessible or precise. Engineers now have sophisticated means at their disposal.

Real-world Examples of NPSH Calculation

Imagine a chemical processing plant dealing with volatile fluids that require precise measurements of their pumping systems' NPSH.

In 2016, a large chemical manufacturer faced significant issues due to cavitation within their primary pumping systems, resulting in frequent operational disruptions. To rectify this, they meticulously calculated the NPSHa and integrated high-efficiency pumps designed to handle their complex fluid dynamics.

For another example, consider a wastewater treatment facility where engineers must manage various fluctuating liquid levels. They employ advanced NPSH calculations to ensure their pumps operate efficiently despite being subjected to different elevations and potential debris blockages.

Power generation plants also illustrate the use of exact NPSH computations, especially in handling condensate pumps. Here, maintaining a proper NPSH margin becomes crucial to ensure the reliability and longevity of essential equipment in high-pressure conditions.

In every scenario, understanding and applying NPSH principles ensure smooth, efficient, and cost-effective operations.

Challenges in NPSH Measurement

NPSH measurement presents numerous challenges that can hinder accurate determination and, ultimately, pump performance.

Understanding these challenges is crucial for engineers seeking to optimize their systems.

Measurement flaws can occur due to fluctuating environmental conditions impacting the suction system. Variations in temperature, pressure, and fluid properties directly affect the accuracy of NPSH calculations, necessitating precise data for reliable results.

Furthermore, the presence of dissolved gases or entrained air bubbles in the liquid can complicate NPSH measurements, leading to incomplete vapor pressure data and miscalculation. Therefore, adopting advanced diagnostic techniques and equipment is paramount to overcoming these impediments and ensuring optimal pump performance.

Improving NPSH in Pump Systems

Achieving a sufficient net positive suction head (NPSH) directly impacts pump efficiency, reliability, and longevity. Therefore, a crucial aspect of this optimization involves adopting various strategies.

Elevating the suction tank level is an effective technique to increase the static head component.

Additionally, minimizing friction losses within the suction piping is essential, with strategies including the use of larger-diameter pipes and reducing sharp bends.

Ensuring the fluid temperature remains low can also bolster the NPSH available, as vapor pressure decreases with a drop in temperature.

Subsequently, selecting pump systems specifically designed for low NPSH applications is vital, enabling optimal operation even under less-than-ideal suction conditions.

Ultimately, the more the NPSHa exceeds the NPSHr, the more robust the pump's performance. Implementing these measures fosters a more optimized and resilient pump system.

Future Research Directions in NPSH Analysis

The future of NPSH analysis holds promising potential for advancing pump technology.

In 2024, researchers should prioritize developing new computational models to enhance the accuracy and reliability of NPSH calculations. These models would help predict NPSH available (NPSHa) under varying operational conditions, ultimately reducing costly errors in system design.

Moreover, investigating the impact of non-Newtonian fluids on NPSHa can broaden the application of centrifugal pumps in industries dealing with complex fluids. This research could offer invaluable insights for sectors like food processing and pharmaceuticals.

Another promising area is the exploration of advanced materials to construct pump components with lower susceptibility to cavitation damage. Innovations in material science could prolong pump life and improve efficiency by minimizing cavitation impacts.

By continuing to push the boundaries of current knowledge, the pump industry stands to achieve significant improvements in both performance and reliability.

Glossary of Terms:

Centrifugal Pump: A centrifugal pump is a mechanical device designed to move fluids by converting rotational kinetic energy to hydrodynamic energy. It uses an impeller to create a flow by centrifugal force, making it ideal for transferring liquids in various industrial applications.

Vapor Pressure: Vapor pressure is the pressure exerted by a vapor in thermodynamic equilibrium with its liquid at a given temperature. It indicates the tendency of a liquid to evaporate and is a critical factor in determining the boiling point of the liquid.

Hydraulic System: A hydraulic system is a complex arrangement of interconnected components, including pumps, valves, actuators, and fluid reservoirs, designed to transmit and control power through the use of pressurized fluids. It is widely used in machinery and equipment to perform various mechanical tasks.

Pump Curve: A pump curve is a graphical representation of a pump's performance characteristics, showing the relationship between the flow rate and the head (pressure) produced by the pump. It helps in selecting the right pump for specific applications and understanding its operational limits.

Suction Lift: Suction lift refers to the vertical distance between the liquid source and the pump's impeller when the pump is positioned above the liquid level. It is a critical factor in determining the pump's ability to draw fluid into the system.

Impeller: An impeller is a rotating component of a centrifugal pump, featuring vanes or blades that transfer energy from the motor to the fluid, causing it to flow and increase in pressure. It is essential for the pump's operation and efficiency.

Absolute Pressure: Absolute pressure is the total pressure exerted on a system, measured relative to a perfect vacuum. It includes atmospheric pressure and any additional pressure applied by the fluid or gas within the system.

Atmospheric Pressure: Atmospheric pressure is the pressure exerted by the weight of the Earth's atmosphere at any given point. It varies with altitude and weather conditions and is a crucial factor in various scientific and engineering calculations.

Total Discharge Head: Total discharge head is the total height that a pump can raise fluid, combining the static discharge head, friction losses in the discharge piping, and any additional pressure head. It represents the energy imparted to the fluid by the pump.

Cavitation: Cavitation is the formation and collapse of vapor-filled cavities (bubbles) in a liquid, caused by localized low-pressure zones within the pump. It can lead to significant damage to the pump's impeller and other components, reducing efficiency and lifespan.